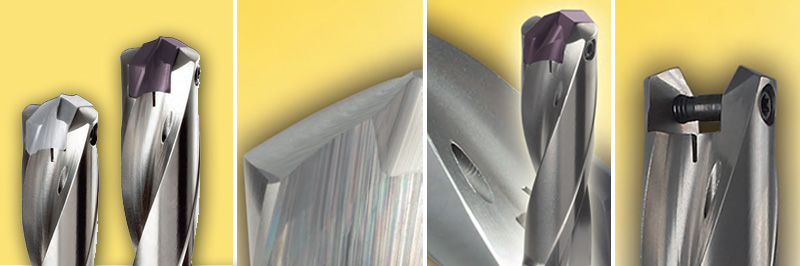

The Interchangeable Insert Drilling System

For highly-accurate large ø holes

The ideal drilling system for the production of large, highly-accurate holes in a variety of materials for wind and water power stations, engine plants or gas/steam turbines.

With the new HT 800 WP interchangeable drilling system Guhring provides high-performance and cost-efficient holders for holes in the diameter range from 11.00 to 40.0 mm that excell thanks to the following advantages:

Extended tool life

Thanks to special, micro-machined cutting edges and the application oriented surface finish the interchangeable inserts of the HT 800 WP drilling system are especially wear resistant.

The holders of the HT 800 WP drilling system also possess a very high wear resistance. This is based on the optimised holder material with nickel plated surface as well as incremental holder sizes in steps of 0.5 mm up to diameter 31.99 mm and in steps of 1.0 mm above diameter 32.00 mm. This leads to less wear on the holder body.

Optimised chip flow

Thanks to their flute cross section the holders of the HT 800 WP drilling system ensure optimal chip evacuation from the hole even with larger drilling depths.

Perfect cooling lubrication

A perfect cooling lubrication is ensured by coolant ducts with maximum cross section, exiting in the flute. Thereby enabling an optimal cooling lubrication of the cutting edges and additionally support the chip evacuation from the hole.

Highly accurate and rigid insert seat

The accurate insert seat enables the insert change in the machine in only a few, simple steps with a standard Torx screw driver. Thanks to the optimised material for the holders of the HT 800 WP drilling system, the insert can be changed more frequently than with conventional systems before the holder needs to be replaced due to wear of the insert seat.

The clamping screws with screw lock ensure a secure holding of the interchangeable insert in the holder even with machines subject to high levels of vibrations.

Rigid holders

The close stepped diameter jumps with the holder sizes not only reduce wear. Through the better guidance of the tool in the hole they also increase the rigidity of the HT 800 WP drilling system. Subsequently, resulting in longer tool life as well as improved workpiece surfaces.

Interchangeable Inserts

HT 800 WP interchangeable inserts are in respect of tool material, geometry and surface finish perfectly adapted to your specific range of application. Subsequently, you will always achieve optimal machining results with maximum performance and highest economic efficiency. The insert change with HT 800 WP can be performed in the machine problem-free, the interchangeable insert always sits perfectly clamped and positioned in the holder. From diameter 26.00 up to 40.00 mm regrinding of inserts is possible.

| Guhring No. | 4112 | 4115 | 4113 | 4114 | 4111 |

| Tool Material | solid carbide | solid carbide | solid carbide | solid carbide | solid carbide |

| Surface | nanoFire | nanoA | FIRE | bright | nanoA |

| Point Geometry | 2-facet | relieved cone | 2-facet | relieved cone | 2-facet |

| Point Angle | 140º | 140º | 140º | 140º | 145º |

| Tolerance | h7 | h7 | m7 | h7 | m7 |

| Diameter | 11.0 - 40.0 | 11.0 - 40.0 | 11.0 - 40.0 | 11.0 - 40.0 | 11.0 - 40.0 |

| Application | stell | stainless steel | cast iron | aluminium | pilot drilling |

|

|

|

|

|

Interchangeable Insert Holders

HT 800 WP holders offer highest accuracy and rigidity. The open flute together with internal cooling guarantees an optimal chip evacuation particularly from deeper holes. The reinforced shank to DIN 6535 HE ensures the strong and accurate clamping of the holder in the tool holder. As it meets the DIN standard for solid carbide monoblock tools, a problem-free changeover to the HT 800 WP system in production is possible at any time.

| Guhring No. | 4105 | 4106 | 4107 | 4108 | 4109 | 4110 |

| Drilling Depth | 1 x D | 1.5 x D | 3 x D | 5 x D | 7 x D | 10 x D |

| Diameter | 11.0 - 40.00 | 11.0 - 40.00 | 11.0 - 40.00 | 11.0 - 40.00 | 11.0 - 31.99 | 11.0 - 31.00 |

| Shank | DIN 6535-HE | DIN 6535-HE | DIN 6535-HE | DIN 6535-HE | DIN 6535-HE | DIN 6535-HE |

45º pilot drilling/ countersinking |

|

|

|

|

|