Typical Reaming Errors Troubleshooting Guide

Low cutting speed, high feed rates as well as the use of good cooling and lubricating agents provide the basis for good reaming practice.

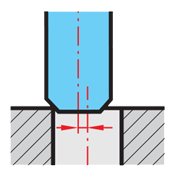

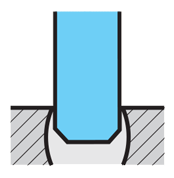

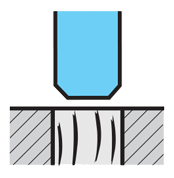

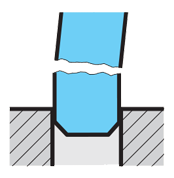

A further point to be considered is that a reamer – an exception is the machine bottoming reamer – always follows the direction of the pre-drilled hole. Subsequently, reamers do not correct alignment errors of pre-drilled holes. Errors between the spindle axis and the axis of the pre-drilled hole can be adjusted with the aid of floating holders.

The following fault finding chart will be found useful in tracing the cause of some common reaming problems.